INDIAN ARMED FORCES CHIEFS ON

OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

SP Guide Publications puts forth a well compiled articulation of issues, pursuits and accomplishments of the Indian Army, over the years

I am confident that SP Guide Publications would continue to inform, inspire and influence.

My compliments to SP Guide Publications for informative and credible reportage on contemporary aerospace issues over the past six decades.

- Prime Minister witnesses 'Bharat Shakti' – a Tri-Services Firing and Manoeuvre Exercise in Pokhran, Rajasthan

- Interim Defence Budget 2024-25 — An Analysis

- Union Defence budget 2024

- Prime Minister Modi Commemorates Indian Navy Day in a Grand Ceremony

- Prime Minister Modi Flies in the LCA Tejas

- New Chapter in India-Italy Defence Ties

- Airpower beyond Boundaries

The F-35 Joint Strike Fighter — A Troubled Endeavour

There is a need to improve the quality of project management to enable the US armed forces to realize the full potential of this new generation platform in a respectable time frame.

|

By Air Marshal B.K. Pandey (Retd) Former Air Officer Commanding-in-Chief of Training Command, IAF |

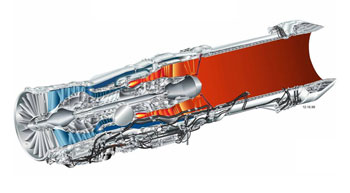

In a report submitted to the lawmakers in the United States (US) on April 27 this year, the Inspector General (IG) of the US Department of Defense (DoD) has warned of the possibility of substantial cost escalation as well as delay in the F135 aero engine project being executed by Pratt & Whitney, an engine manufacturer of global repute. The F135 engine which was derived from the F-22’s F119 engine, is meant to power all the three versions of the F-35 Lightning II, Joint Strike Fighter (JSF), a fifth generation combat aircraft designed, developed and built by an aerospace industry team led by Lockheed Martin Aeronautics of the US. Other major industry partners in the F-35 project include Northrop Grumman, BAE Systems and Pratt & Whitney. The focus of the report by the IG, DoD is essentially on mismanagement of the F135 project which the report says would contribute to the cost escalation and delay in the F135 project which in turn will affect the F-35 project as a whole.

An Ambitious Project

The F-35 Lightning II JSF is a single-seat, single-engine, all-weather multi-role combat aircraft with stealth features. It is regarded as the most ambitious and expensive venture ever undertaken by the DoD in the regime of aircraft acquisition. The objective of the project is to simultaneously develop three variants of the aircraft, a conventional version for the United States Air Force (USAF), a carrier version for the United States Navy (USN) and a short-takeoff and vertical-landing version for the United States Marine Corps (USMC). The objective of the exercise was to develop a single stealthy, supersonic, multi-role aircraft to replace those in service. This single platform would be capable of all roles including aerial combat, deep-strike and battlefield support. The F-35 will also be supplied to eleven other nations who are either members of the NATO or are close allies of the US. These nations some of whom are also active partners in this project, are the United Kingdom, Italy, Australia, Canada, Norway, Denmark, the Netherlands, Japan, South Korea, Israel and Turkey.

The F-35 has been developed from the Lockheed Martin X-35, which was preferred over the Boeing X-32 that was competing for the F-35 Lightening II, JSF contract worth over $200 billion. Launched on October 2001, the first prototype of the F-35 Lightening II, JSF undertook its maiden flight on December 15, 2006, undoubtedly an impressive beginning. The USAF, the USN and the USMC are looking forward to replacing their legacy fighters soon. The USAF has already begun to receive the new platforms, the USMC expects to induct the aircraft by summer this year and if all goes according to plan, the USN is likely to begin inducting the aircraft by 2018. Deliveries of the F-35 for the US military are scheduled to be completed in 2037. As against the total order of 2437 aircraft, so far only 220 aircraft have been delivered.

The F-35 project has been plagued by cost overruns and delays since it was launched in 2001.

A Turbulent Journey

After the successful maiden flight that was achieved in five years, the F-35 project has thereafter been plagued by cost overruns and delays. Over the last 14 years, the project cost has increased by 43 per cent. As per the the Government Accountability Office (GAO) report on the F-35 project prepared in 2014, the acquisition programme would need $12.6 billion per year up to 2037. The most recent cost estimate for operating and supporting the F-35 fleet is more than $1.5 trillion, which the DoD may find a burden that is difficult to carry. The cost of the already expensive F-35 Lightenting II JSF has gone up by more than $113 billion over the originally estimated level. In the year 2014 alone, the project cost has gone up by $4.3 billion.

One component of overall cost escalation has been the rise in the cost of the power plant. As of 2012, the cost of the F135 engine had gone by nearly ten per cent to $63.8 billion. The original equipment manufacturer attributed this escalation in cost to increase in the cost of spare parts. The engine manufacturer is still completing a redesign of the F135 to correct a deficiency that grounded the entire fleet in 2014. The US GAO earlier this month expressed concerns that reliability problems continue to plague the F135.

The President of Military Engines Business at Pratt &, Whitney, Bennett Croswell however, countered the findings of the GAO pertaining to the reliability of the F135 engine. He is of the view that the F135 engine is reliable and that changes in the design of the engine had been validated and were being incorporated into the fleet. Croswell felt that “The GAO has confused engine spec reliability and aircraft spec reliability, which are measured differently".

During an inspection and appraisal of the F135 project at Pratt & Whitney, the IG DoD observed violations of management procedures. The inspecting officers identified as many as 61 instances wherein key regulatory requirements were either not complied with or even blatantly violated. These deficiencies were found in the areas of Programme Management Oversight, Critical Safety Item Compliance, Continuous Improvement, Risk Management, Supplier Management and Software Quality Management. The Inspectors felt that over 50 per cent of the cases of non compliance with regulatory requirements were of a serious nature as these could result in the failure of the Quality Management System.

The Pentagon's F-35 Joint Program Office (JPO) while admitting that the report is factually correct, does not agree with all of the findings and recommendations outlined in the report. The JPO is of the view that some of the recommendations for corrective action "are unnecessary, and, if implemented, would add cost and delay to the programme for items that are already well understood and carefully managed”. Croswell added that for the past six months, the company had been addressing the findings of the IG. He said none of the deficiencies found in the company's management processes affected engine reliability and that all but one of the issues would be corrected by July this year.

As of 2010, the Pratt & Whitney F135 engine was regarded as the most powerful power plant ever installed in a fighter aircraft.

Power Plant Issues

An alternative power plant for the F-35 Lightening II JSF designated as the F-136, was also being developed jointly by General Electric and Rolls-Royce. However, for some reasons amongst which cost was probably the most important one, the project was cancelled by its manufacturers in December 2011. That left the field open for the Pratt & Whitney F135 engine which had a higher thrust rating as compared with the F-136. As of 2010, the Pratt & Whitney F135 engine was regarded as the most powerful power plant ever installed in a fighter aircraft.

While Pratt & Whitney has been struggling with a host of problems with the F135 engine project, in June last year, the already difficult situation for the company was compounded further on account of a major catastrophic failure of the engine. Following the engine fire on takeoff on June 23, 2014 that caused extensive damage to the F-35 aircraft, the fleet was grounded for some time. Also, a new set of restrictions were imposed in its operation in the air as well as on the ground making it not only difficult but sometimes even impossible to complete flight and ground test schedules. As no proper solution to the problem with the engine has been found, some of these restrictions may remain in place for a considerable time, further impeding progress of the F-35 project. This will definitely cause a delay in the Initial Operational Clearance and subsequent induction of the variant for the USMC.

Project Management

Apart from the cost escalation and the tardy progress that afflicts the F135 engine project which in turn has its share of impact on the F-35 programme as a whole, there are a number of other issues that have and continue to plague the project to develop the most expensive weapons system ever in the history of the US. When the F-35 project was launched in 2001, the DoD unveiled plans to purchase 2,852 aircraft valued at around $233 billion. This figure was scaled down to 2457 later. As per initial stipulations, the first squadron of the F-35 was to be operational in 2010. However, as of now, the project is lagging behind by at least seven years. Observers are of the view that the project has been executed with a development strategy that has been full of risks, its management has been poor and the oversight has been somewhat indifferent. Besides, the design itself has had inherent flaws requiring expensive corrective changes and modifications. All these have resulted in burgeoning costs.

Another problem area has been the development of the technologically advanced pilot’s Helmet with in-built devices that is expected to provide unprecedented capabilities to the pilot for acquiring and tracking targets as well as for weapon delivery. Unfortunately, the development of the highly complex and elaborate software for this unique Helmet to deliver its full potential, is reported to be lagging behind. This will undoubtedly impinge on the operationalisation of the platform, apart from rise in cost. As of date, the aircraft not only lacks full-scale weapons delivery capability but all-weather operations capability as well.

Some observers are of the view that the problems of the F-35 project are also attributable to Pentagon’s hands-off management policy. Pentagon believed that as government oversight was unduly restrictive and expensive, empowering the contractors would be a better option. Unfortunately this turned out to be a case of grave misperception.

While the DoD and the prime contractor may not be able to do much to undo the failings of the past, there is certainly the need and the scope to improve the quality of project management to enable the US armed forces to realise the full potential of the this new generation platform in a respectable time frame.